The right product

in the right box

in the right place.

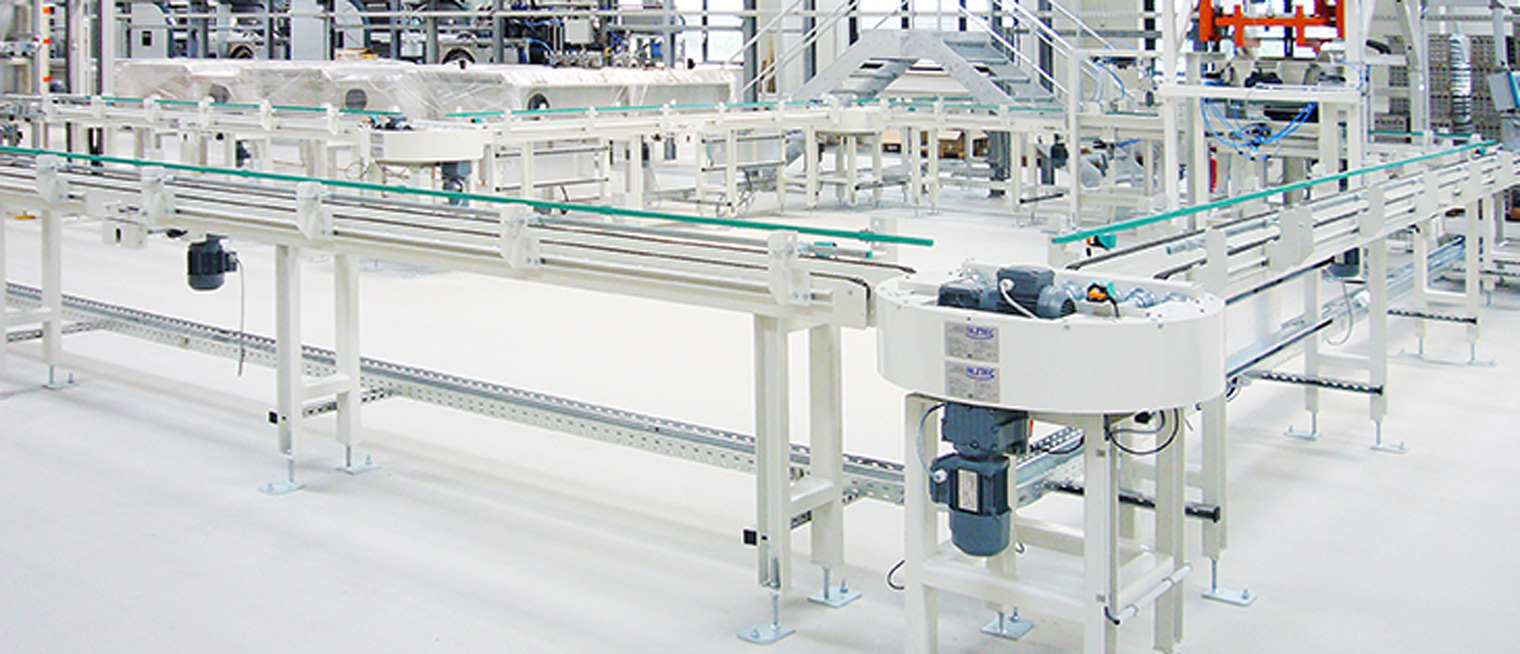

The task

Conveying

In a galvanizing workshop, the non -treated parts were delivered by the customers in Bito-boxes. In the plant, these must be put into special baskets so that they then can pass several dipping baths. After the galvanic treatment, the parts have to be put back into the cleaned Bito-boxes.

The solution

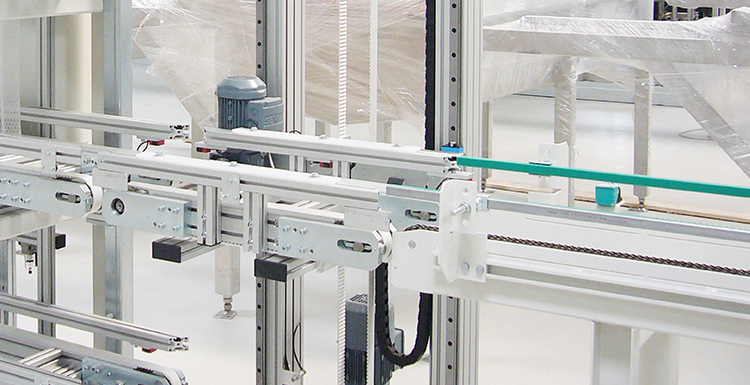

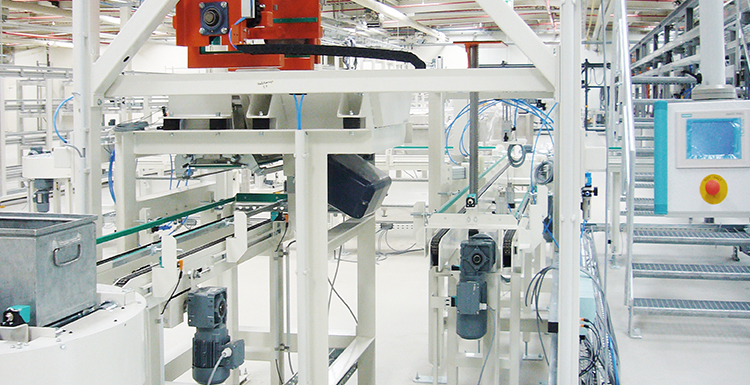

For the conveying of the Bito crates and baskets, chain conveyors were used throughout. Rotary tables implemented all direction changes in the plant. The transfer units include a gripper to accept the boxes or baskets, a lifting station with transverse chassis for the transfer to the funnel and a rotary unit that puts the parts into the funnel after which the parts are transferred into the boxes or baskets. Alztec designed the complete Conveyor technology including the rotary tables, lifters, tilting station, turning station and cover plate handling. After the production of the components at well-known manufacturer companies, we installed the complete mechanics at the end customer. The electrics and the control technology were carried out by a general contractor.

Facts & figures

Capacity: 720 pcs./day

Alztec Team:

12 EE in design

8 EE in assembly and commissioning

4 EE in electrics and control engineering

Main components:

160 m conveying track

4 lifters

12 rotary table

4 transfer units

1 tilting units

2 turning stations 1 Cover handling

Videos

Video Conveyor technology 1

Video Conveyor technology 2

Video Box Buffer

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.