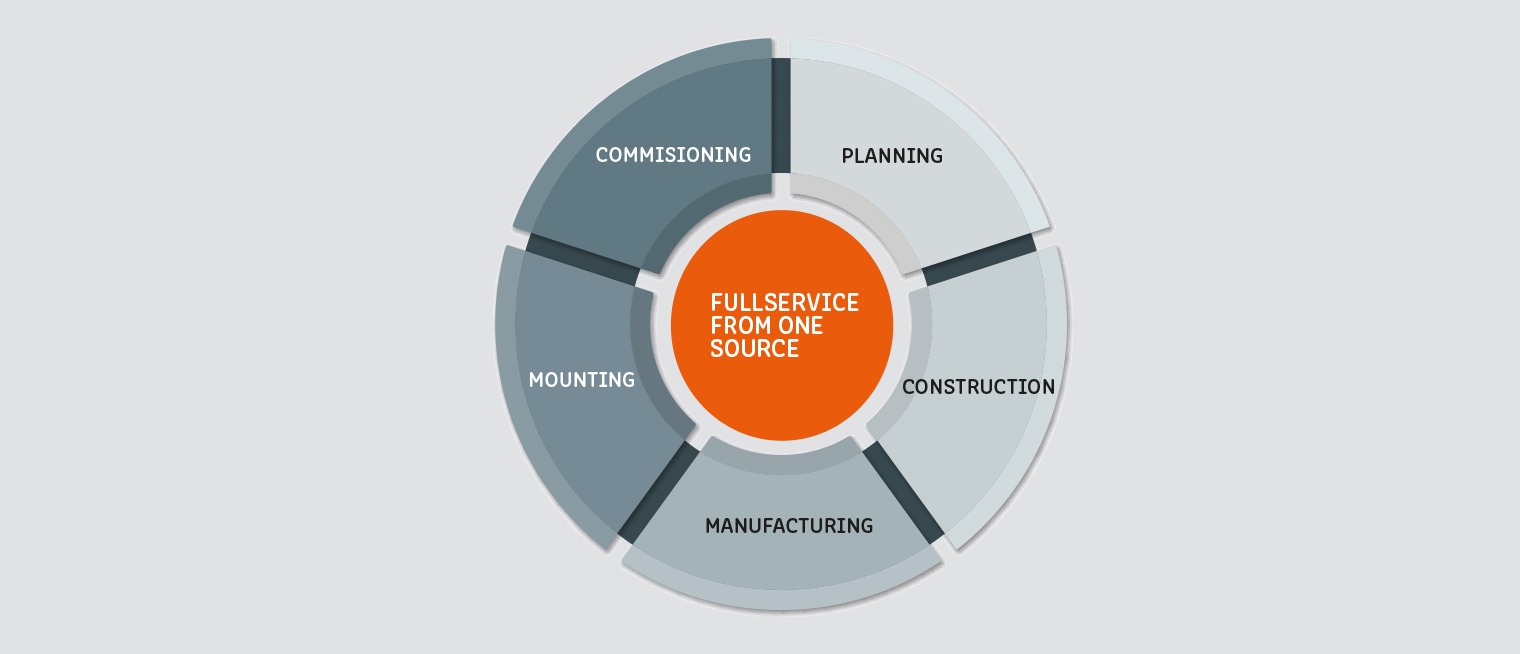

Warehouse solutions designed to boost your logistics for maximum efficiency. Alztec has just the right solution for you.

Alztec’s know-how opens up exceptionally advantageous opportunities for you in intralogistics and storage technology. Individually tailored to your needs from the broad basic portfolio or specially developed for you. Talk to the Alztec experts and obtain useful information about your project. Everything is possible. The Truemaker are ready for you.

Example

Heavy-duty applications

Heavy weights.

Minimal space.

High redundancy.

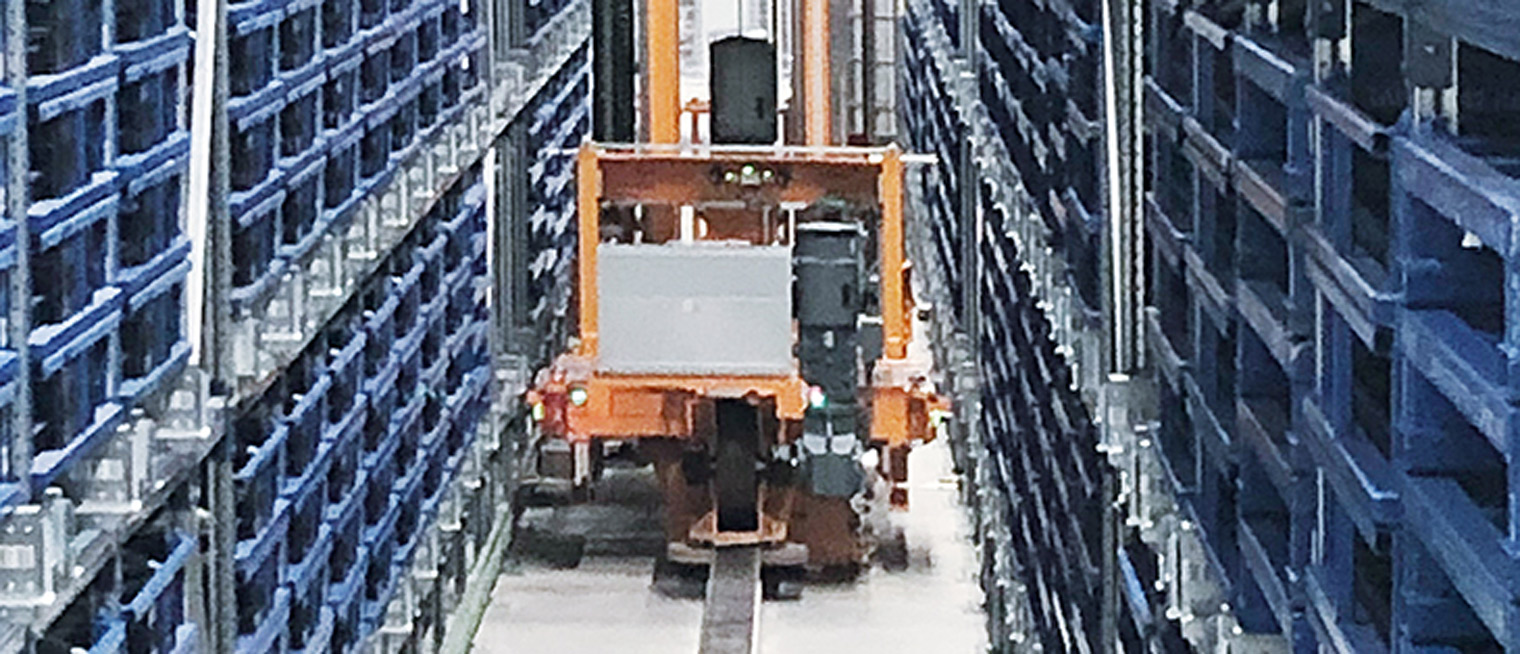

The task

Conveying

Storage

Battery modules or vehicle batteries as well as basic pallets and empties should be able to be stored at two locations. In both warehouses, products should be able to be loaded and unloaded at the front and rear. The stack weights range up to 2.5 tons.

The solution

For maximum redundancy both warehouses feature two aisles each. A long and a narrow warehouse are designed as single deep structures each. Both stacker cranes are equipped with telescopes. The second warehouse with its square footprint features two aisles and multiple deep shelves. The lifting platform on the stacker crane is equipped with a charging station to allow wireless satellite movement into the channels. Both stacker crane types are designed for handling payloads up to 2.5 tons.

Facts & figures

Capacity: 500 stacks/day

Payload: 2.5 tons

Alztec team:

4 design & engineering staff

16 assembly & commissioning staff

8 electrical & control engineering staff

Main components:

2 aisles, single, deep

2 stacker cranes with telescope

2 aisles, multiple, deep

2 stacker cranes with satellite

2 plant control systems including visualization

2 warehouse management systems

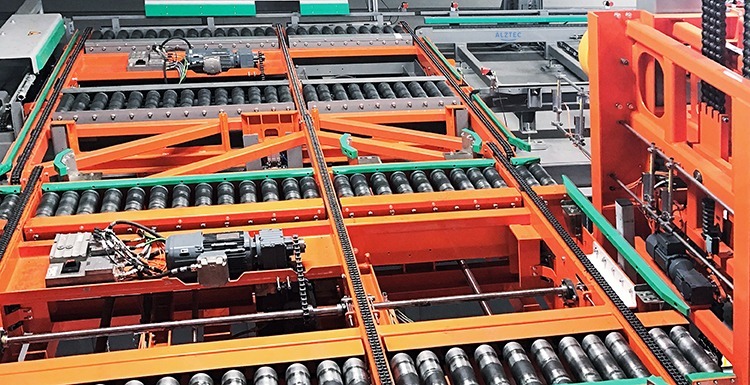

Example

Automated warehouse

Commissioning in a big way!

The task

Conveying

Storage

Handling

Plastic parts are painted in an automotive plant. The end customer’s requirement is to provide the more than 600 possible different parts (in unmixed containers) in a specific order in picking containers and to store as many containers as possible (unmixed, empty and full picking containers).

The solution

The unmixed container arriving at the goods receiving area is measured fully automatically and placed on a load carrier with a staple-module. Given the large number of containers, it was challenging to securely grip all of them and turn them so that the opening would later face the worker. The load carrier incl. product is transported to the corresponding storage area on the 1st floor. On the ground floor, picking is carried out by the customer’s employees. At 6 stations, the station lifter provides the corresponding unmixed containers according to a predefined sequence. The employees remove parts from the containers provided one after the other and fill a picking container. Each of the 6 stations has its own range of parts and geometrically different picking containers. The finished picking containers are transported by a double distribution truck and returned to the warehouse via a lifter and stacker crane. There, the picking containers are waiting to be called off to the assembly line, fed to it, emptied and returned. In order to cover the high cycle time, a total of 8 stacker cranes are used on 3 rails, each 150 m long.

Facts & figures

Capacity: 250 pcs./day

Alztec team:

10 EE in design

20 EE in assembly / commissioning

8 EE in electrics / control engineering

Main components:

3 aisles with

8 stacker cranes with telescope

1 shelf

9 lifters

1 double-distribution trolley

5 distribution trolleys

2 staple-modules (rotating)

2 staple-modules

230 metres conveyors

900 load carrier

48 commissioning gates

1 system control including visualization

1 warehouse management system

Example

Dynamic

commissioning

Just in sequence –

when every second counts –

at 424 storage bays.

The task

Conveying

Storage

In order to supply the production line of a luxury car manufacturer with the necessary parts, a fully automatic system is required. The workers at 424 variable storage locations are always provided with the appropriate components enabling the pre- commissioning of these components.

The solution

Alztec plans and supplies the complete material flow system tailored to the assembly sequence of the final assembly line. One of the main requirements are the speed and the reliability of the rack servicing. In order to satisfy the elevated speed requirements of 4.5 m/s at a load capacity of 1,000 kg; the rack servicing equipment specifically has been designed for this application. In order to guarantee the required reliability. It has been equipped with redundant motors.

Facts & figures

Capacity: 1.440 pcs./day

Alztec team:

12 EE in design

16 EE in assembly / commissioning

6 EE in electrics/ control engineering

Main components:

6 rack alleys

6 rack servicing equipment

170 meters shuttle high-level track

6 shuttles

150 metres conveying track

1 lifter

2 stacking modules

1 plant control including visualization

1 warehousemanagementsystem

Example

Automatic

storage system for small

load carrier containers

Always the appropriate components

in the right place.

The task

Conveying

Storage

Handling

In order to pre-sequence a production line for gear assembly, an automatic storage system was to be set up in an automobile plant.

The aim is to have a fully automatic supply and collection by the tugger train.

The solution

In addition to the usual requirements that an automatic warehouse has to meet, the challenge here was to develop a stacking/destacking module that optimized the storage technology of the incoming stacks before storage and sorted the individual small load carrier containers that had been mixed up from production into stacks that could be picked up.

Alztec engineers successfully implemented this as well as the subsequent connection of an additional aisle and two robot cells for loading a washing machine.

Facts & figures

Capacity: 3.100 pcs./day

Alztec team:

6 EE in design

12 EE in assembly / commissioning

4 EE in electrics / control engineering

Main components:

4 rack alleys

4 rack servicing equipment

2 robots

14 racking modules

8 lifters

1 automated cover handling

250 metres conveying track

1 plant control iincluding visualization

1 warehousemanagementsystem

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.