Unique

Alztec Silicon

processing know-how

Alztec has been developing innovative and advantageous methods for processing polysilicon for over 20 years. Starting with harvesting the U-Rods, through crushing and screening, to final packaging. Maintenance equipment such as washing systems, grinding machines and electropolishing systems are also available in tried and true Alztec quality.Everything is possible. The Truemaker are ready for you.

Example

Packaging plant

for granular

silicon

Highly compact packaging

under pressure.

The task

Conveying

Handling

A Chinese-American joint venture company was looking for a special solution for compact, automated packaging of granular silicon. The silicon granules are delivered through a pipeline with a special coating and should be packed in bags of 10kg (±10g) with a vacuum of 200 mbar. At the end of the system, fully automatically packed cartons are to be output on weatherproof packed pallets. A throughput of at least 200 bags per hour is required.

The solution

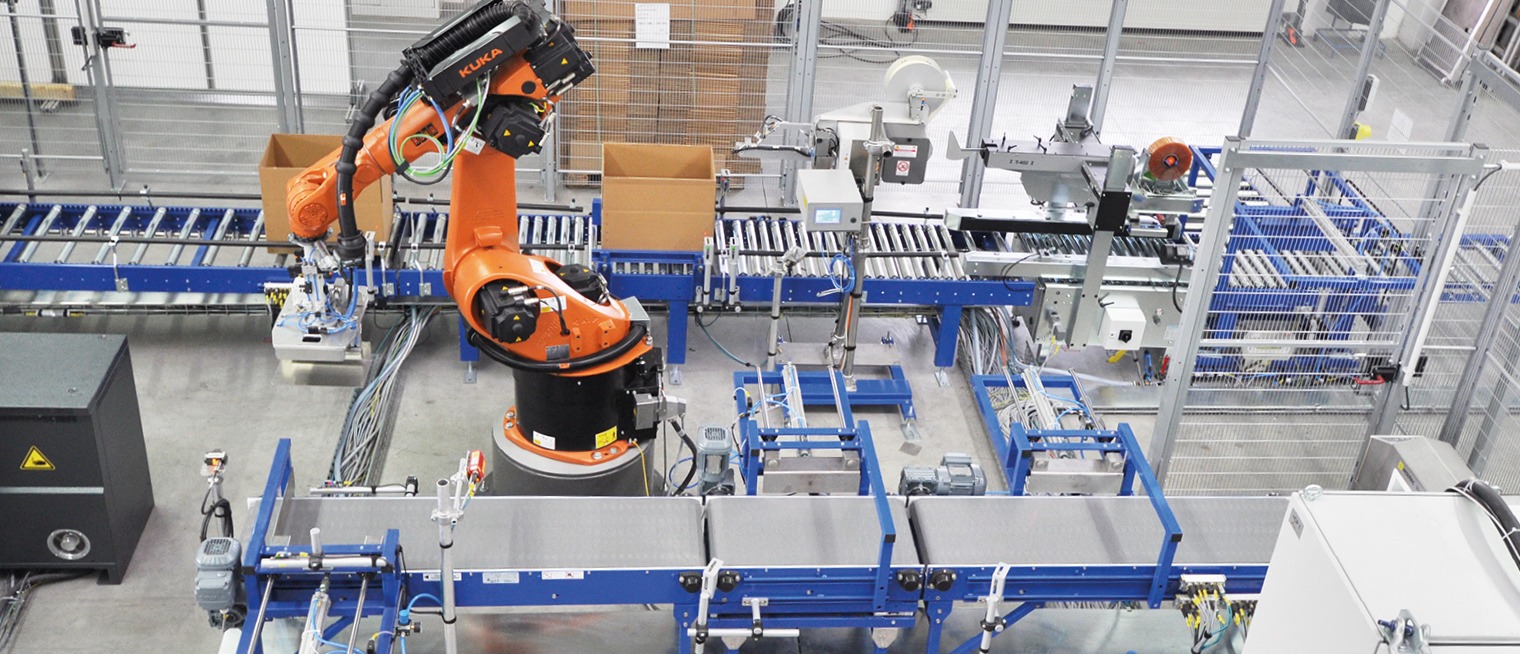

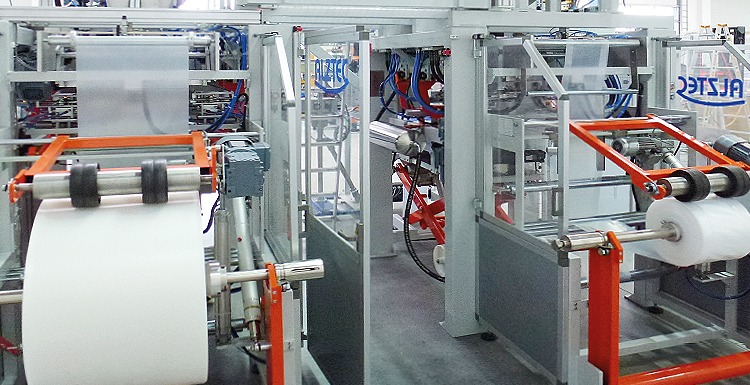

The silicon granules produced in a new process can now be packed fully automatically using the special Alztec system. The Alztec team achieves the task with two VFFS (VERTICAL FORM FILL and SEAL) packaging systems, in which the bag is first made from foil material, then filled, evacuated and finally sealed.

The material is double-bagged, both bags are labeled and, after checking the weight and metal, they are packed into cartons by a robot. The carton is then stacked on a pallet by another robot. The filled pallet is weatherproof packed and can be removed with the forklift at the end of the system.

A special challenge was the coating of parts that come into contact with the product with silicon nitride and the high negative pressure in the bag, which could be solved by the Alztec know- how.

Facts & figures

Capacity: 5.000 tons/year

Alztec team:

5 EE in design

8 EE in assembly / commissioning

6 EE in electrics / control engineering

Main components:

1 packaging plant inner bag

1 packaging plant outer bag

80 metres bag conveying means

1 clean room lock

1 metal detector

1 robot cell for bag packaging

1 box lifter / closing

30 metres box conveying engineering

1 robot cell for palletizing

5 labeling

25 metres pallet conveying engineering

1 stretch binder

1 plant control including visualization

1 material management system

Example

Processing plant

for polysillicon

Parts per trillion –

highest purity –

unique Alztec

process.

The task

Conveying

Processing

The world’s largest producer of polysilicon wants to automate the breaking, sorting, cleaning and packaging of polysilicon and increase the purity of its product. The facility is intended to process 4,000 t of high-purity polysilicon for further use in the electronics industry. The customer material is brought to the system in logs of approx. 70 kg each. In the end, the broken and cleaned polysilicon should come out of the plant fully automatically in bags of 5 kg (±50 g). Additional requirements are the high purity < 500ppt and the exact material tracking according to SEMI criteria.

The solution

Alztec designed and supplied this revolutionary system including the material management system. The high level of purity was achieved using special materials and patented processes.

The crushing of the polysilicon is realized by non- contact high-voltage pulse breaking with 200 KV and 5 Hz, which already ensures a high purity of the polysilicon at this stage. In a next step, the crushed material subdivided by a special wet screen equipment into various fractions is filled into several etching baskets. Some µm of the surface are eroded by wet chemical processes through a connected etching plant, ensuring thereby a maximum cleanliness. Finally, the ultra-clean material will be dried and packed into PE double bags.

Facts & figures

Capacity: 4.000 tons/day

Alztec team:

8 EE in design

10 EE in assembly / commissioning

6 EE in electrics / control engineering

Main components:

1 high voltage impulse breakage

1 screening equipment

150 metres basket conveying

300 etching baskets

1 etching plant

1 drying plant

3 bag packaging plant

1 plant control including visualization

1 warehousemanagementsystem

Example

Automation

and materials flow for

a polysillicon factory.

Alztec makes factories

run – all over the world.

The task

Conveying

Storage

Handling

A factory for the production of high-purity polysilicon for the solar industry was planned in the Middle East. In order to ensure the highest quality despite the lack of local specialists, this factory was planned to be predominately automated. Until now, the processing in other factories worldwide has been mainly manual, so Alztec will be introducing new developments and concepts in many areas.

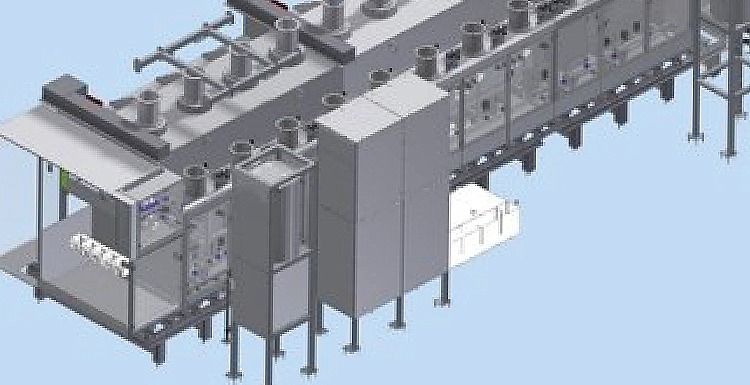

The solution

Alztec finds unique techniques for the automated processing of polysilicon that meet the highest purity requirements for the solar sector. In addition, a complete material management system with batch tracking is supplied.

The entire factory is equipped with Alztec systems, from harvesting the silicon from the CVD reactor to final packaging of the polysilicon ready for sale.

Various processing steps with transport and storage of the silicon rods as well as crushing, sorting, transport and storage of the silicon chunks are implemented.

Alztec also perfectly mastered the challenge of international coordination of the project with a wide variety of requirements such as customs clearance, work permits, cooperation with local companies and authorities, etc.

Facts & figures

Capacity: 8,000 tons/year

Alztec team:

8 design & engineering staff

16 assembly & commissioning staff

8 electrical & control engineering staff

Main components:

2 silicon harvesting plants

330 containers for silicon rods

1 high-bay warehouse for containers

4 crushers

2 extraction systems

180 metres of handling section for boxes

1 high-bay warehouse for boxes

6 packaging plants

110 meters of handling section for bags

1 final packaging system

Various handling systems

4 control systems including visualization

1 materials management system

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.