Custom-made systems, heavy-duty systems.

We make lightweights out of your heavyweights. 3 kgs to 30 kgs – 30 tons to 300 tons? Alztec offers customized solutions designed for your needs and requirements.

Can’t find any off-the-shelf solutions for your automation needs? That’s where Alztec’s custom-made systems come in. Alztec offers systems which are precisely tailored to your needs. Either based on Alztec’s extensive portfolio of existing solutions, rapidly tweaked and configured to meet your specific needs. Or brand new custom-made solutions specially designed and implemented just for you. The sky is the limit. The Truemaker are ready and waiting to serve you.

Cross-plant

material flow of

vehicle bodies

This is where the connection comes into play. Over 400 vehicles are moved per day.

What matters is the bottom line.

Intra factory

material flow of

car bodies II

We establish connections.

Also from factory to factory.

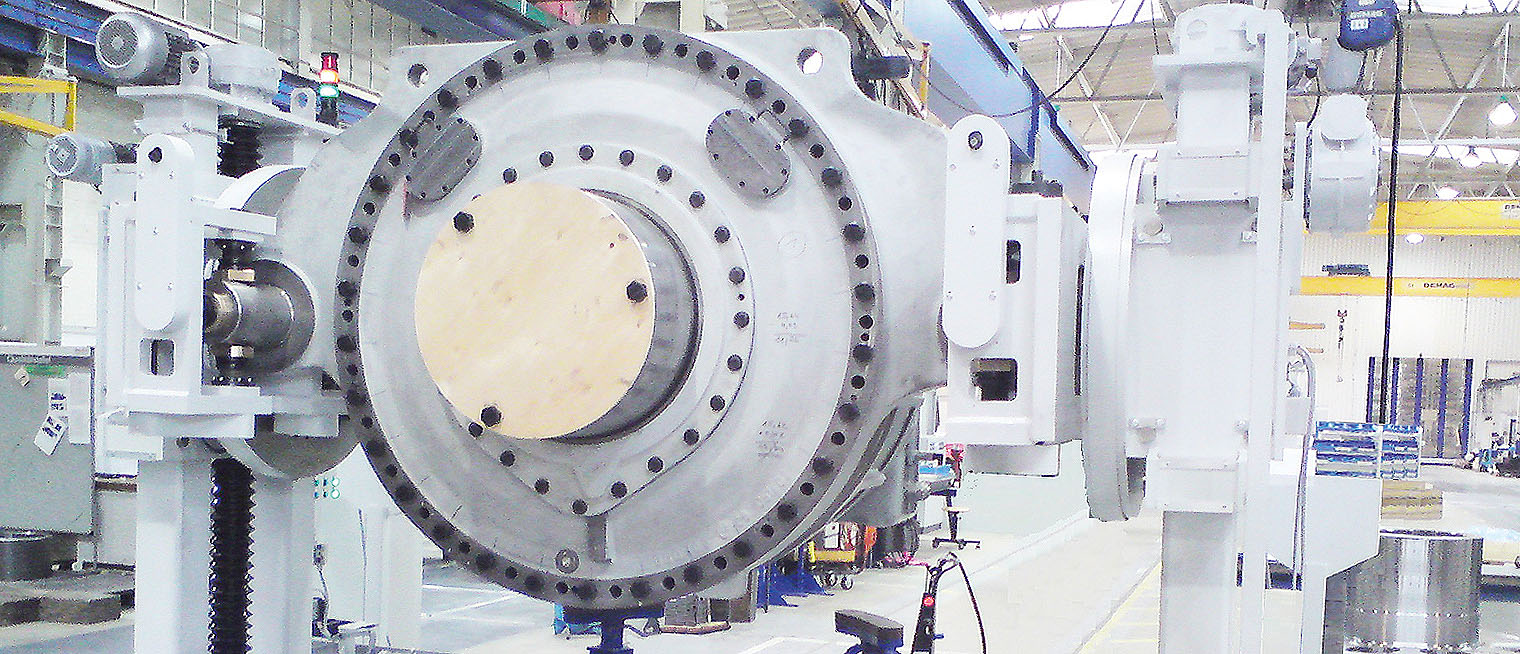

Lifting, rotating device

for wind energy gears

For efficiently rotating

8 categories of heavyweights weighing

up to 32 tons. Easy as a breeze.

Automated

Medicine Transport

We transport your medicine cleanly

from the clean room to the shipping

department.

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.