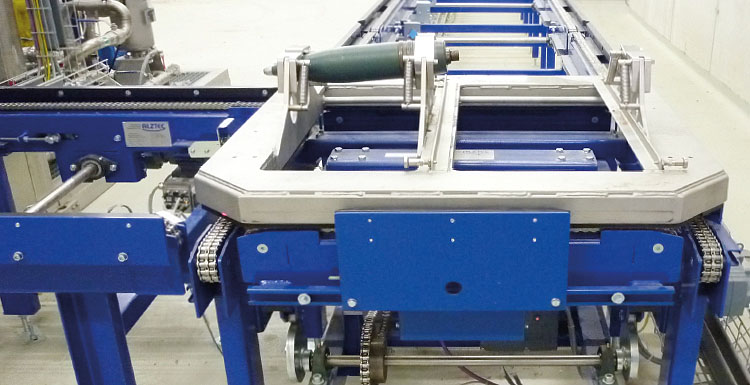

Conveying system

Dynamically clearing the way.

The task

Conveying

In explosion-proof areas, load carriers shall be transported from one production space to the next.

The solution

By the use of proper material pairs, chain conveyors, rotary tables and lifting unit have been developed which by their operation cannot generate any ignition spark. The equipment crosses various areas (fireproof zones) secured by fireproof gates. In a production area. the handling portal removes the product from the load carrier and puts the latter into the processing station. Thereafter the portal removes the component again from the station and puts it again into the load carrier. In order to be able to enter the equipment for maintenance work also inside and to provide it with material from manual lifting cars, a lifting unit with pneumatic control has been developed and installed. Alztec has assumed in this project the complete layout design, the mechanical Engineering as well as the manufacture and installation of the components. The customer took care of the electrical installation and of the control engineering.

Facts & figures

Capacity: 400 pcs./day

Alztec team:

4 EE in design

6 EE in assembly / commissioning

Main components:

150 metres roller conveyors

12 corner conveyors

2 turning devices

2 lifting devices

1 handling device

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.