Heavy load conveying

Gentle giants.

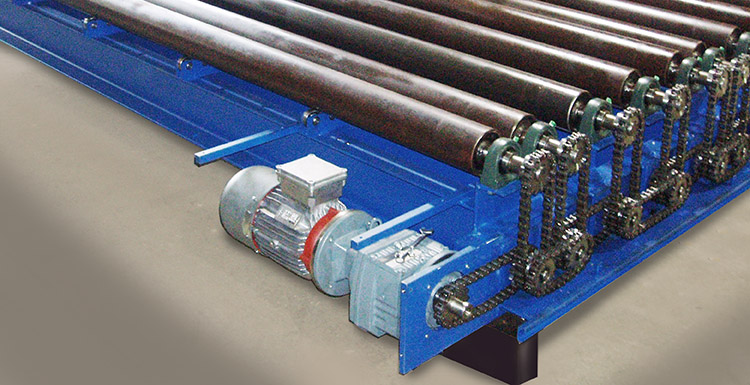

The task

Conveying

Piles of metal sheets are to be automatically stacked in the manufacturing cell and then transported via a conveyor system to the intermediate storage.

The solution

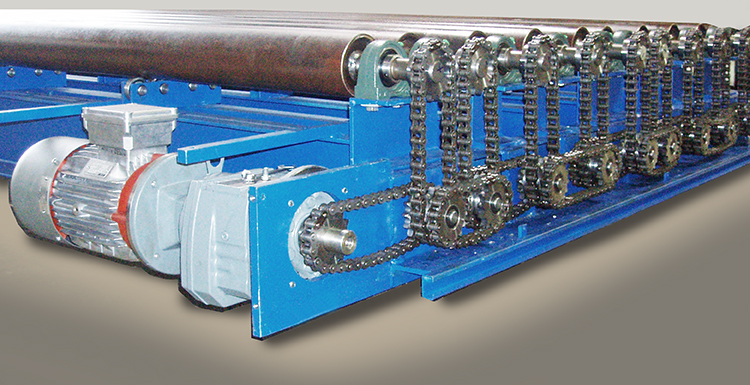

The sizes and weights of the metal plate stacks presented the Alztec engineers with the challenge of designing the conveying means in a way to ensure that the stacks could be transported without failure, despite the weight and distortion factor.

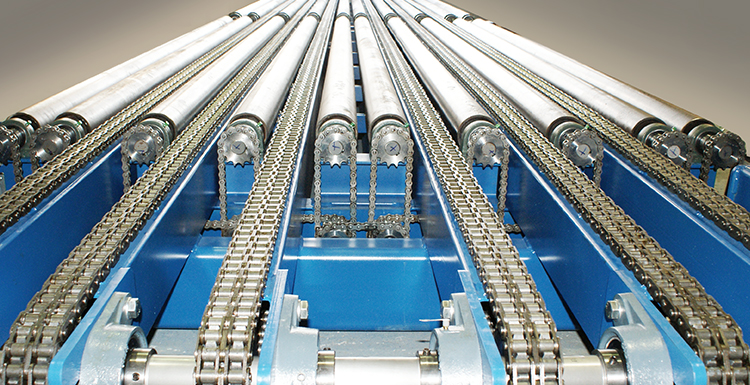

For this purpose, chain conveyors with six tracks, driven on both sides, were designed for the longitudinal transport. The cross transport was implemented by roller conveyors with closer divisions and multiple support rolls below the carrying rolls. The corner conveyor included a hydraulic lifting gear that can lift and lower the chain conveyors with six synchronized hydraulic cylinders.

Alztec supplied and installed the conveying system at the final customer. The manufacturer of the sheet metal plates took over the electrical installation and the control engineering.

Facts & figures

Capacity: 400 pcs./day

Alztec Team:

2 EE in design

3 EE in assembly and commissioning

Main components:

12 m 6-track chain conveyor

30 m roller conveyor

1 hydraulic lifting gear

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.