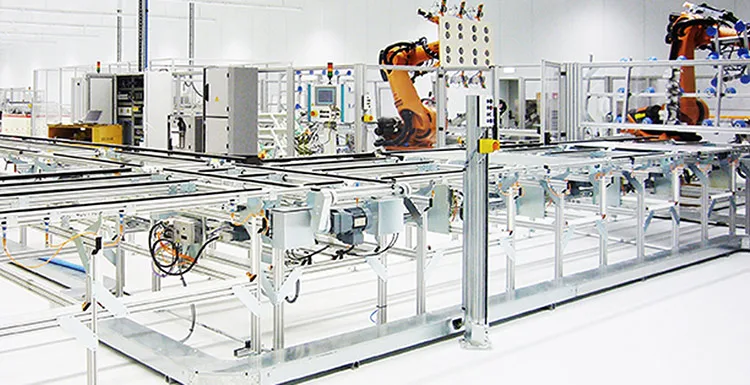

Conveying means for solar panels

From the glass to the

solar panel.

The task

Conveying

A conveying technology was required for the manufacture of solar panels, which would transport the semi-finished panels from one manufacturing position to the next.

The solution

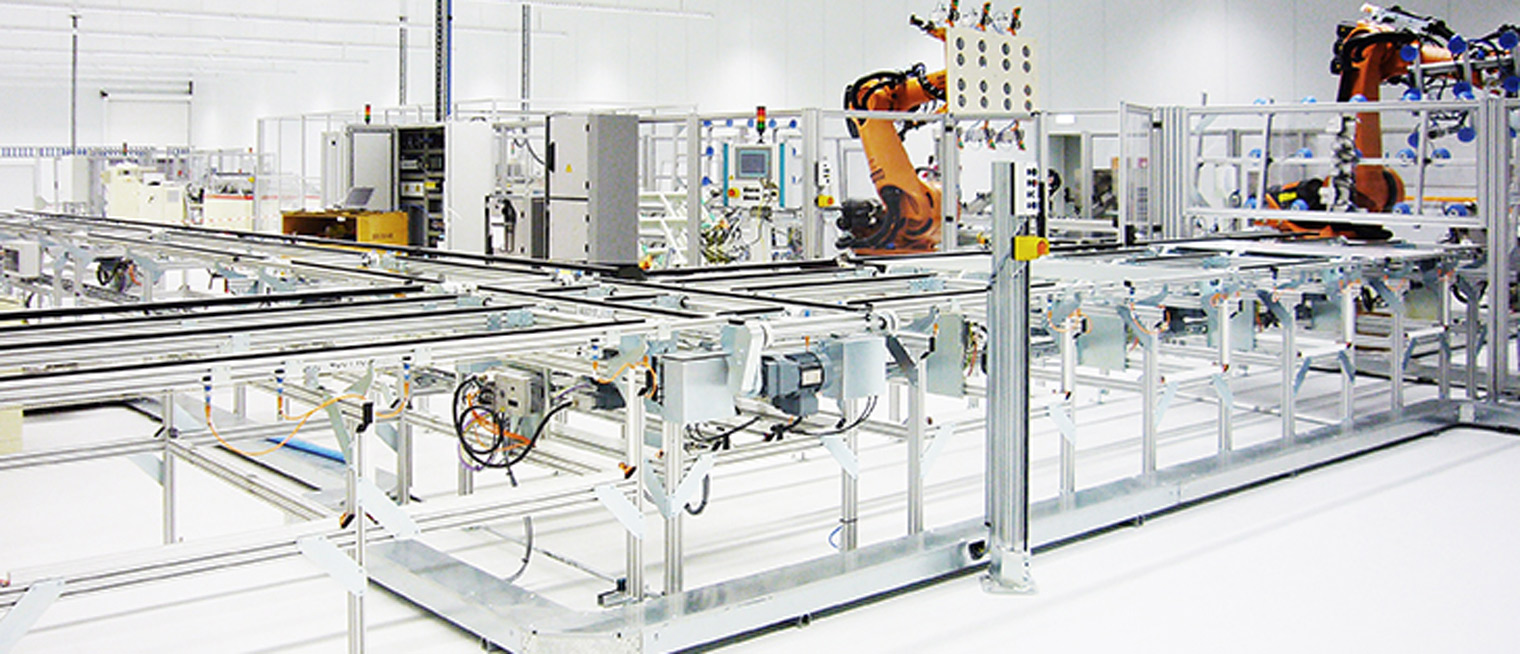

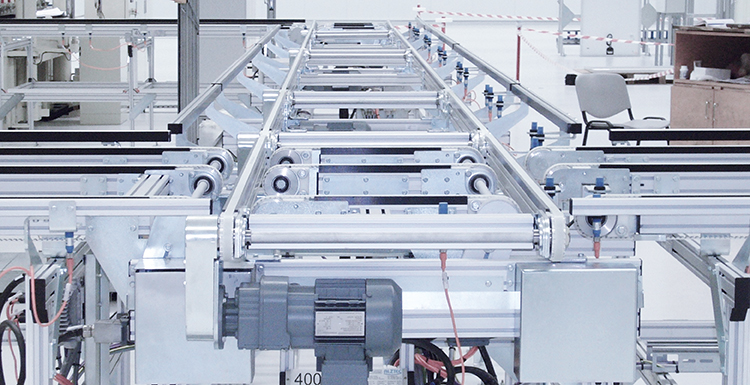

For a smooth transport, timing belt conveyors were developed, which can transport the glass up to the finished solar panel. Depending on the required position of the products, the crossings and branching connections in the conveying systems were implemented with corner conversions or rotary tables. For the transfer of the glass or panels to the robots, assembly devices with suction features were designed and installed at several points in the plant. A worker implemented the quality control at the end of the manufacturing line. For this application, the solar panel was automatically assembled and placed on a non-driven roller conveyor, on which the employee could then carry out the inspections. After the control, the panel was automatically laid down again and transferred to the packaging area. Alztec supplied and installed the complete mechanical and electrical installation of the conveying technology for this project. The plant control system was implemented by the general contractor.

Facts & figures

Capacity: 1.440 pcs./day

Alztec Team:

4 EE in design

2 EE in assembly and commissioning

Main components:

53 timing belt conveyors

8 eccentric lifting gear

3 centering devices

2 rotary tables

4 assembly design

2 tilting tables

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.