Conveying technology for solar

Smooth transport of glass

and solar modules.

The task

Conveying

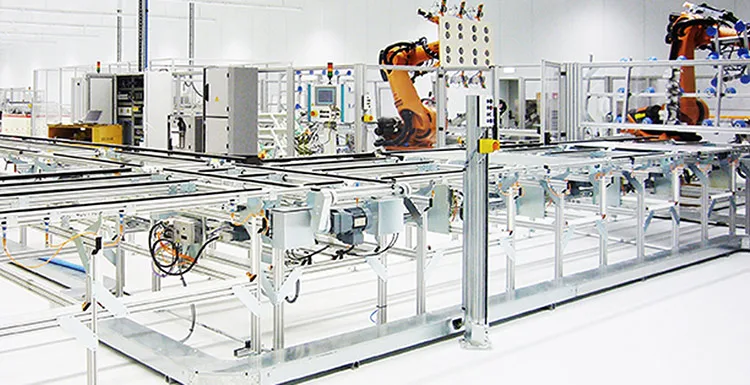

The production of a solar module requires many manufacturing steps. The task was to develop a universal conveying design by which glass and solar panels can be transported from one manufacturing position to the next.

The solution

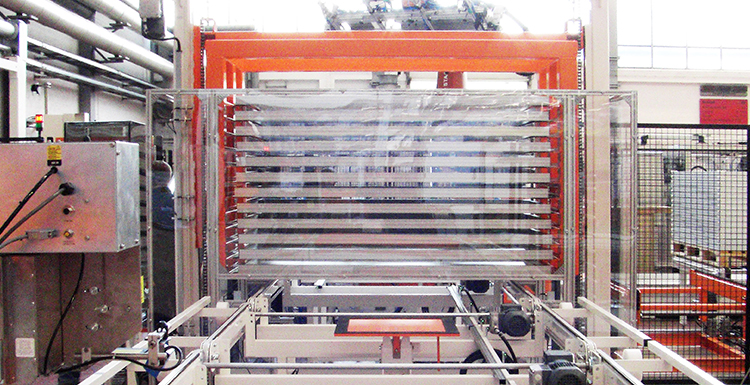

Two and three strand toothed belt conveyors transport the glass and the solar panels smoothly through the plant. Corner conveyors and rotary tables approach the individual manufacturing cells. Centering devices and lifting tables ensure the correct position of the glass and solar panels during production.

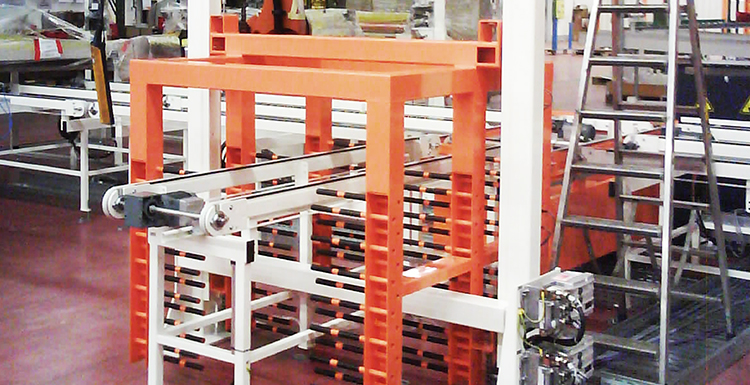

In order to be able to maintain production figures at a high level in a manufacturing cell, and to relieve the system in the event of delays, special FILO buffers (first in – last out) were developed and installed in advance.

Our company was “only” responsible for the construction and production of conveyor technology as well as their mechanical and electrical installation. The manufacturing cells and the complete sequence control were taken over by a general contractor.

Facts & figures

Capacity: 1.440 pcs./day

Alztec Team:

4 EE in design

4 EE in assembly and commissioning

Main components:

137 toothed belt conveyors

23 eccentric lift gears 12 centering devices

6 lifting tables

3 rotary tables 12 FILO buffer

17 chain conveyors

2 distribution cars

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.