Lifting, rotating device

For efficiently rotating

8 categories of heavyweights weighing

up to 32 tons. Easy as a breeze.

The task

Conveying

Storage

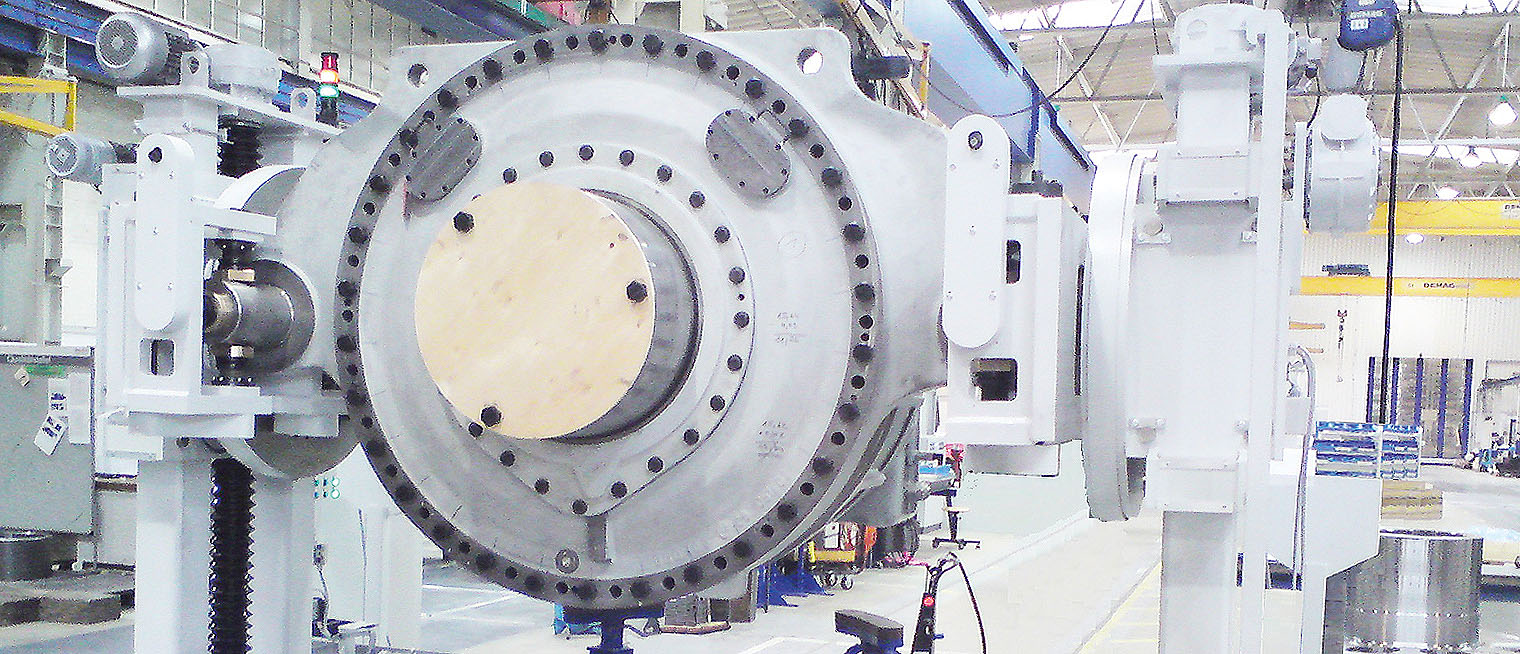

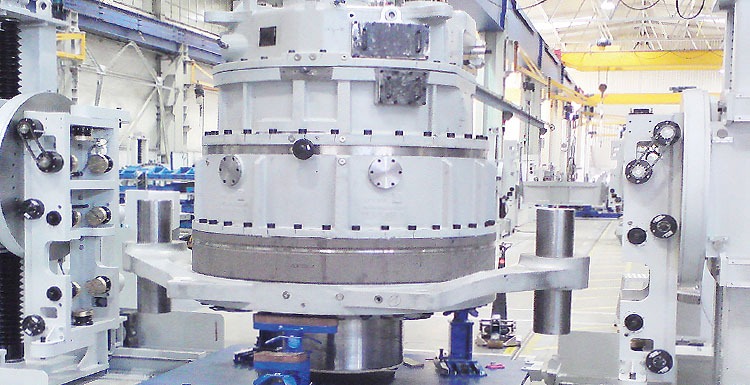

The Alztec customer is setting up assembly lines for wind turbine gearboxes at two locations in Germany and one location in China. During the assembly process, various areas should be made accessible for the employees. To do this, the torque arm to the partially assembled gearbox to the wind turbine, parts which can weigh up to 32 tons, have to be rotated several times.

The solution

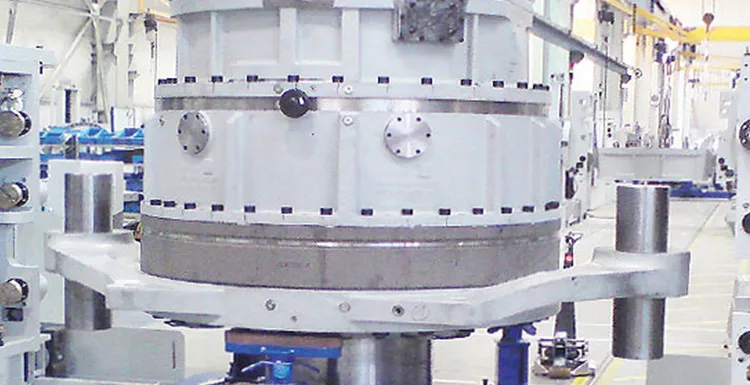

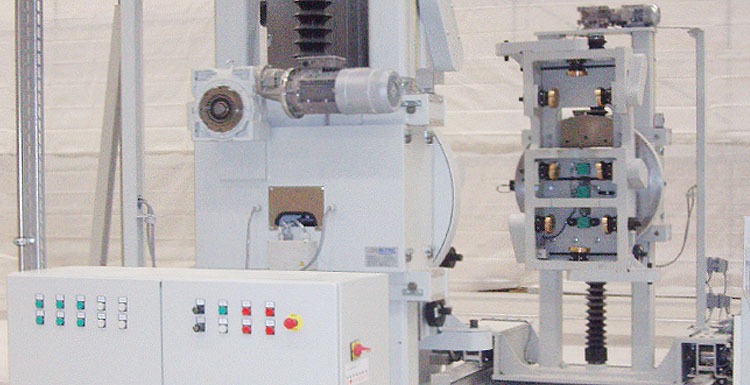

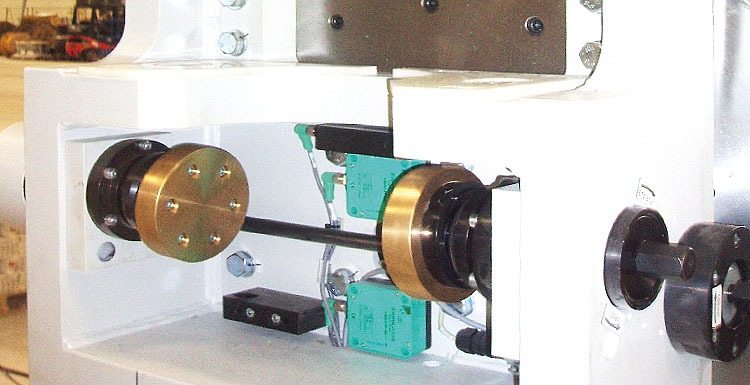

The lifting and turning devices consist of a lifting unit with a trapezoidal thread spindle drive and a turning unit, which is driven by an internally toothed slewing ring. To pick up the components, the lifting and rotating devices are automatically moved together on a rail. The mounting jaws have two different mounts for two different gearbox designs. A total of eight different gear types can be turned on the systems. The control is semi-automatic. This means that the system only moves when the operator presses the consent button. If he releases the button, it stops.

Facts & figures

Capacity: 32 tons

Alztec team:

2 EE in design

3 EE in assembly / commissioning

2 EE in electrics / control engineering

Main components:

3 lifting, turning devices each composed of

2 chassis

2 lifting units

2 turning unit

2 clamping jaws

1 plant control including visualization

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.