Automated

We transport your medicine cleanly

from the clean room to the shipping

department.

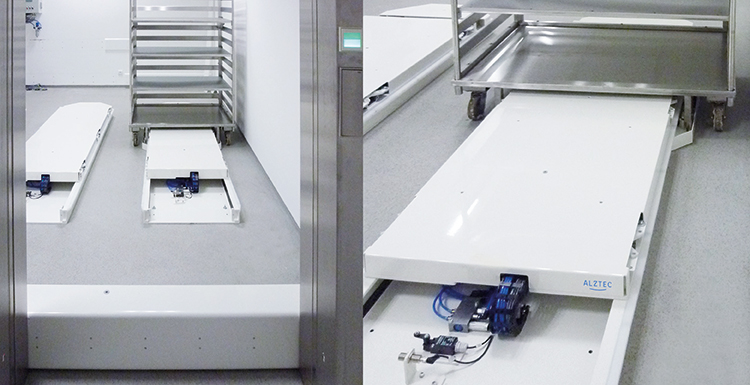

The task

Conveying

Raw products must be transported via a cleanroom airlock (gray room) from goods receiving to production and from production back to shipping (goods receiving).

The products must be transported in the clean room on trolleys, whereby the trolleys may only be moved in the clean room and gray room.

The solution

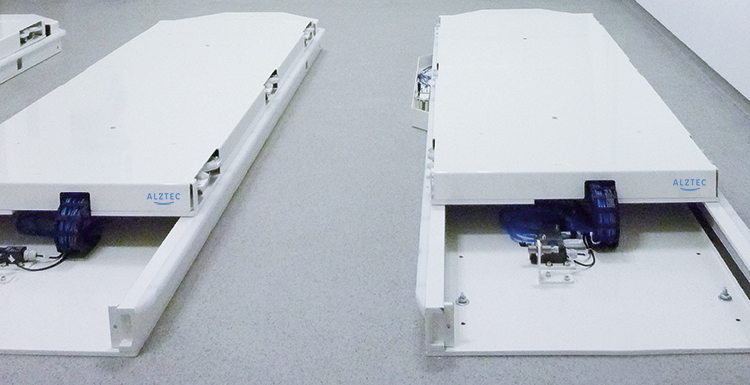

Three floor-mounted transfer systems for longitudinal transport, each with three buffer positions, and a wall-mounted transfer system for transverse transport were installed in agray room. With the toothed belt-driven transport systems, the trolleys are moved on their own rollers by pneumatic carriers.

The trolleys from the clean room can be loaded on two lines (line 1 – full trolleys, line 2 – empty trolleys). Depending on the requirements of the operator at the loading/unloading point, a trolley is transported in front of the transfer point. After opening the door, the operator loads or/and unloads the wagons and sends them to the pickup point on the third line. From there, the trolleys are removed manually. When a line is full, this is indicated to the operators in the clean room and in the goods receiving area visually and with a signal tone.

Facts & figures

Capacity: 12 trolley/hour

Alztec Team:

1 EE in design

2 EE in assembly/commissioning

2 EE in electrics/control engineering

Main components:

3 floor shifting systems

1 wall shifting system

1 system control including visualization

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.