Buffer system for ladder

Almost weightlessly your products fly

into the warehouse.

The task

Handling

Storage

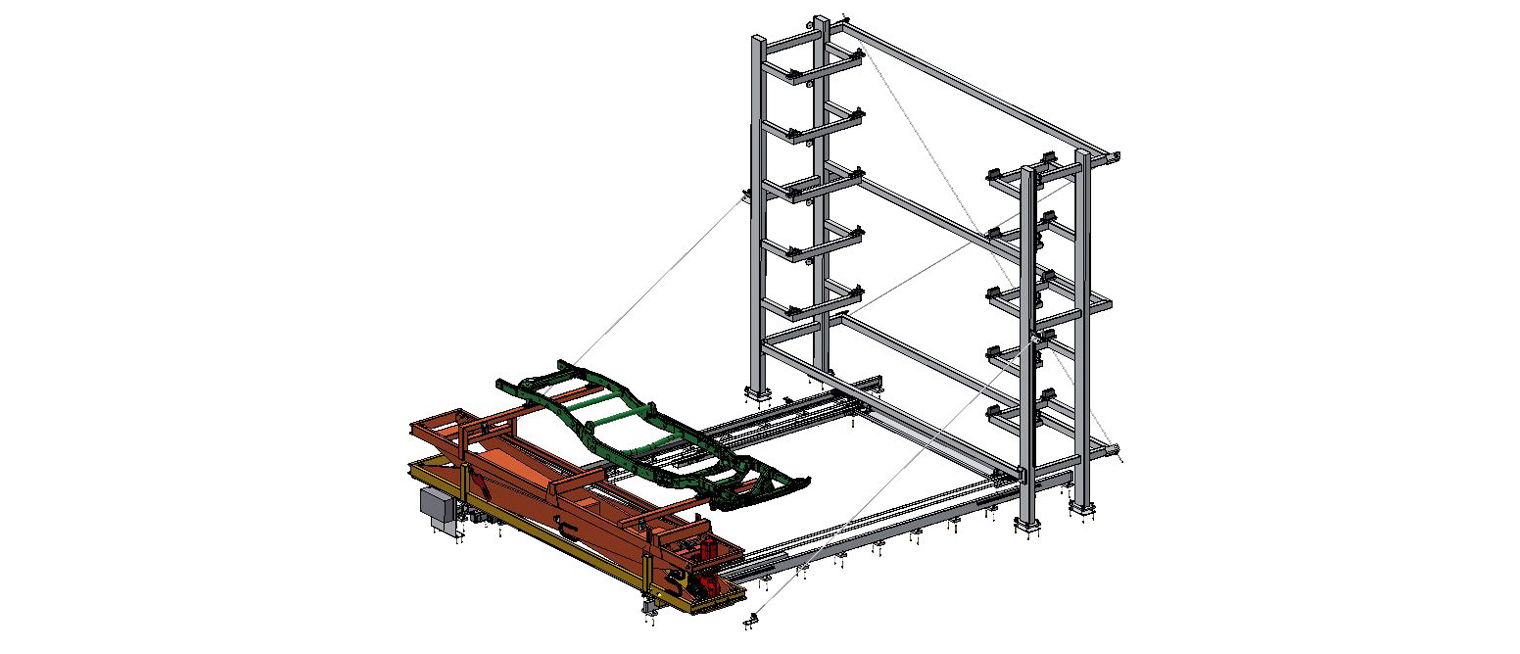

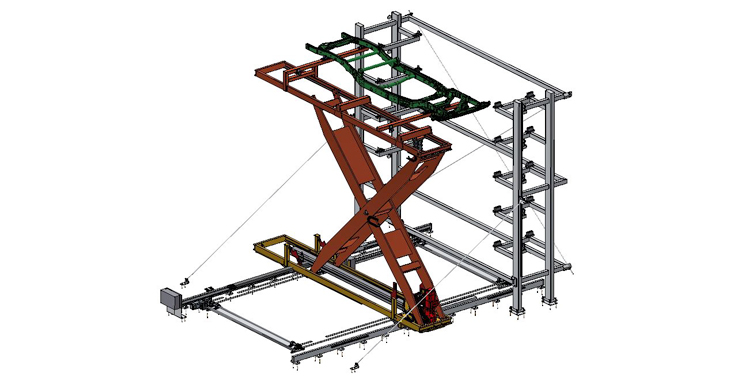

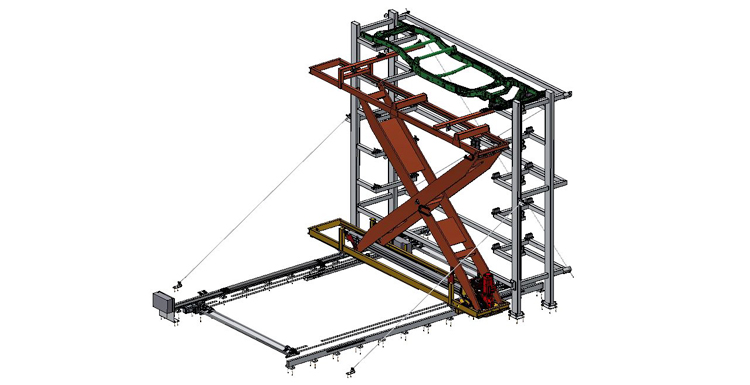

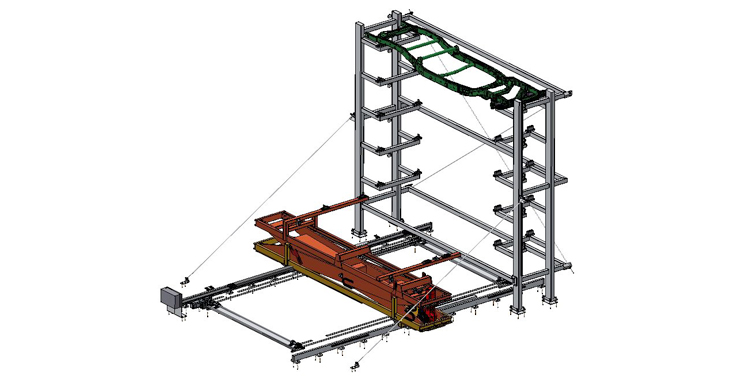

The customer requires a concept and design for two space-saving FIFO storage units for ladder frames of off-road vehicles. The storage should be able to buffer five frames. The takeover and handover is carried out to an on-site overhead conveyor system. The protection technology (protective fence and access protection) is in the scope of the customer.

The solution

The developed concept and its design resulted in a handling module with the following functions:

- Rail-mounted trolley with toothed belt drive for moving the ladder frames.

- Scissor lift system with a push chain for lifting and lowering the ladder frames. The supports on the lifting system are designed cantilevered so that the frames can be moved into a rack.

- By buffering the ladder frames in a rack, each frame can be accessed.

- The driving and lifting positions are determined by a laser distance measuring system.

- For safe and gentle transport and storage, the plastic holders were developed in close cooperation with the customer.

Facts & figures

Capacity: 12 ladder-fames/hour

Alztec Team:

1 EE in design

Essentially planned components:

1 drive axle with toothed belt drive

1 scissor lift with push chain

1 rack with 5 buffer places

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.