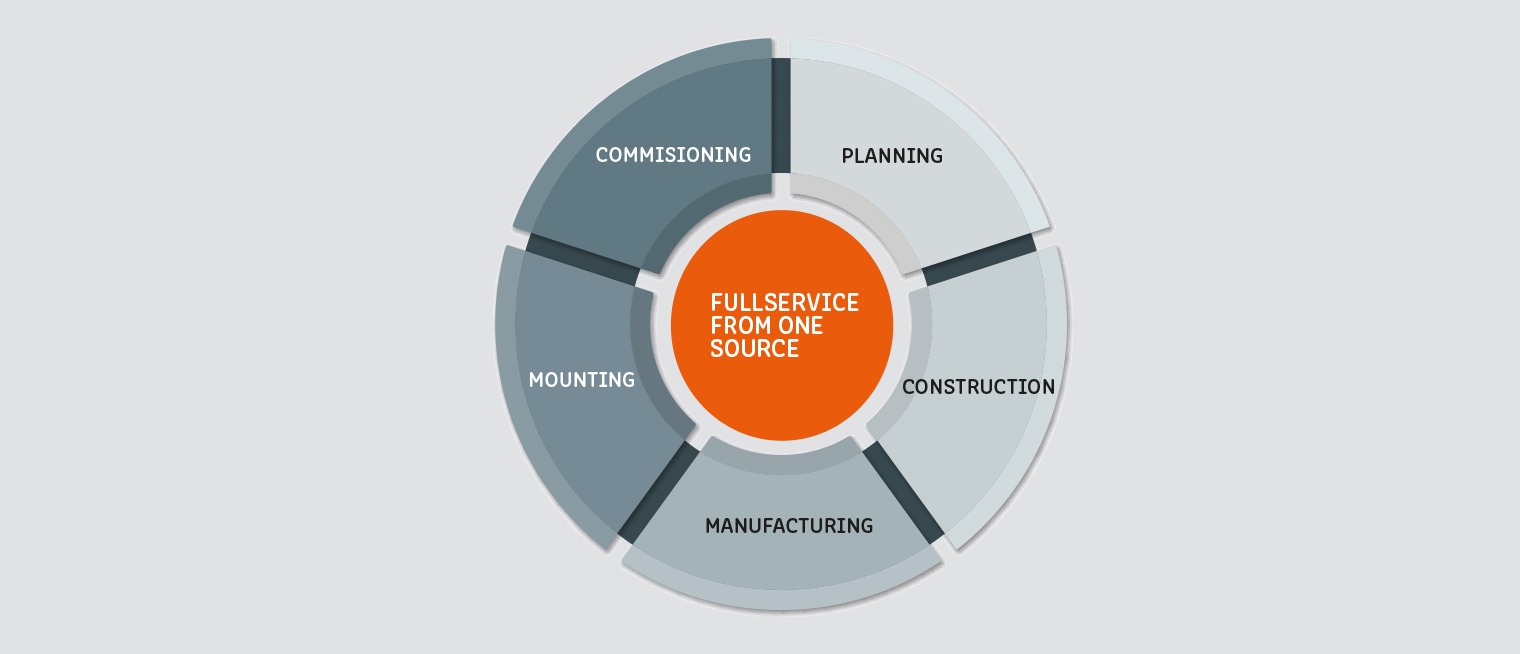

Intralogistics and warehouse solutions.

Warehouse solutions designed to boost your logistics for maximum efficiency. Alztec has just the right solution for you.

Alztec’s know-how opens up exceptionally advantageous opportunities for you in intralogistics and storage technology. Individually tailored to your needs from the broad basic portfolio or specially developed for you. Talk to the Alztec experts and obtain useful information about your project. Everything is possible. The Truemaker are ready for you.

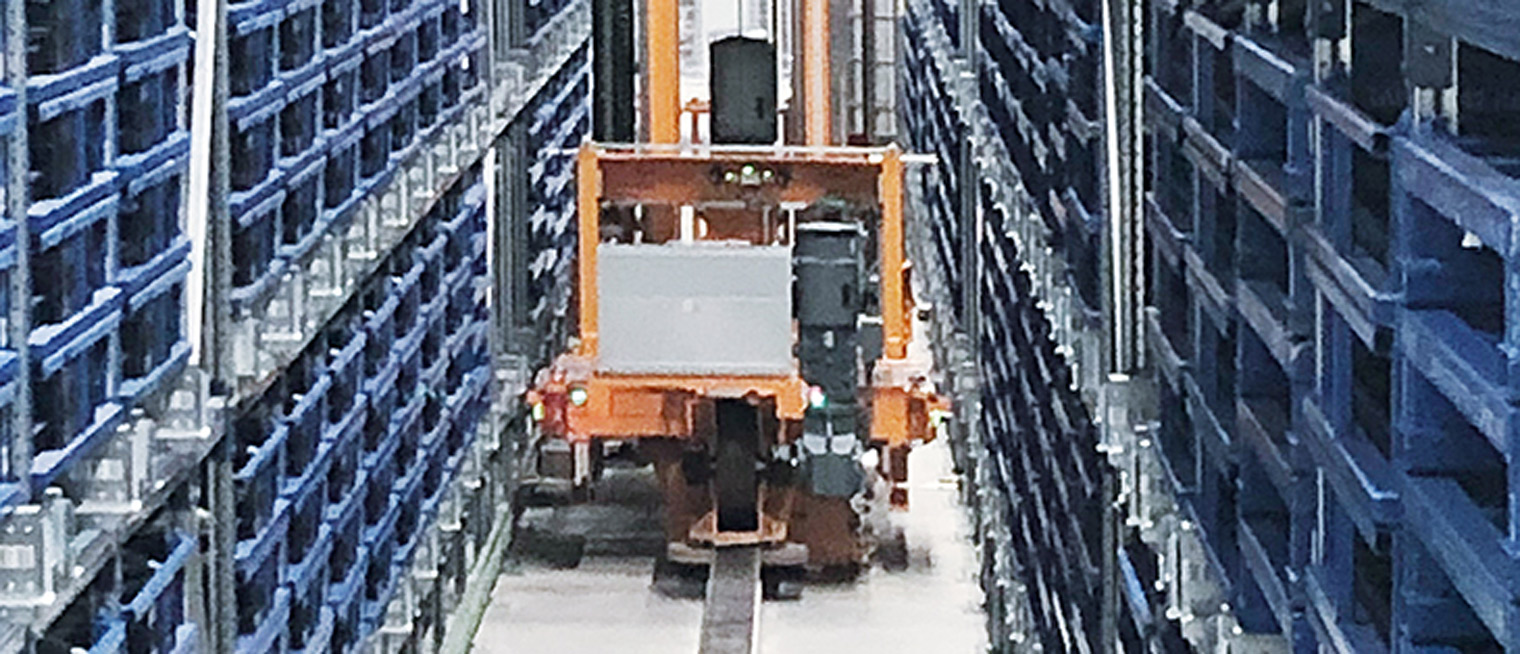

Automatic

storage system for small

load carrier containers

Always the appropriate components

in the right place.

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.