Alztec Engineering.

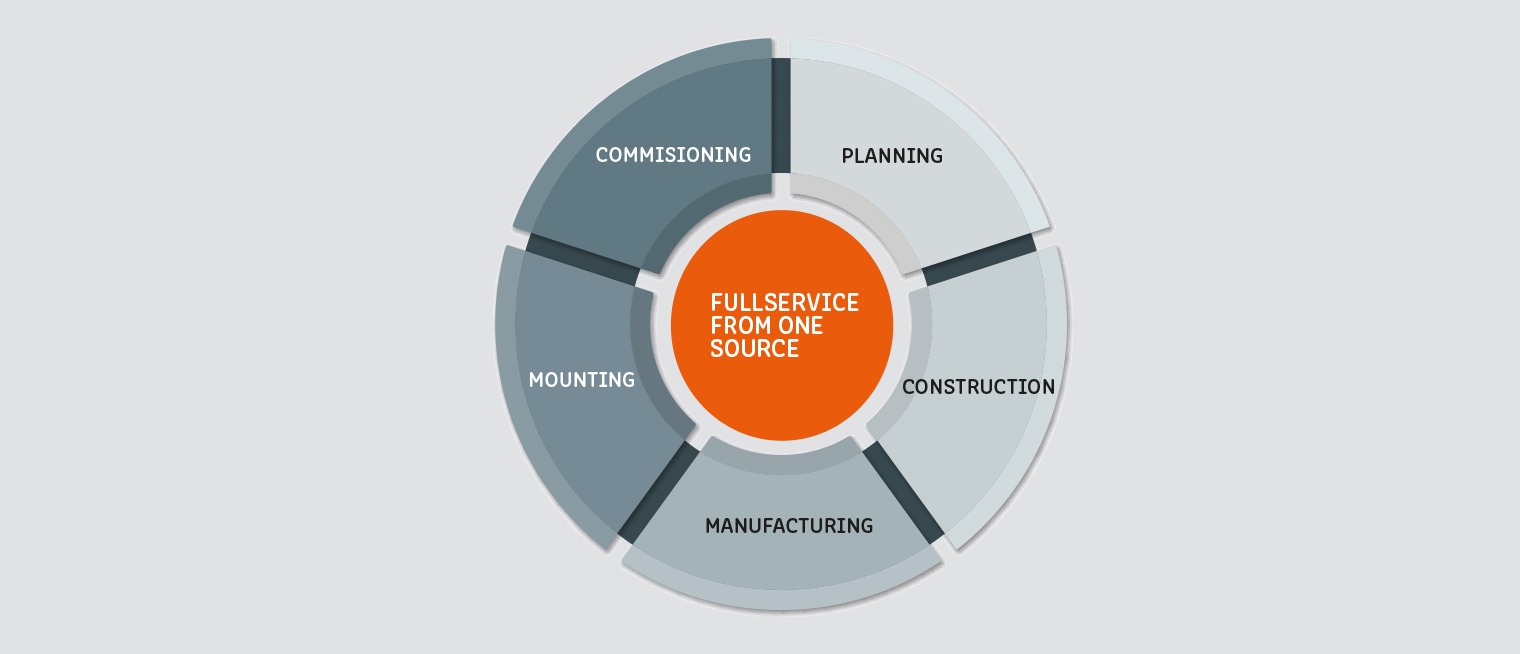

Find out what the term

engine in engineering is all about.

ALZTEC Engineering means receiving top-of-the-line support

to achieve your goals in terms of processes and costs, e.g. based on:

As-is analyses

Feasibility studies

3D designs

We also supply the following services, among others:

Factory design

Plant design

Logistics

Silicon Processing

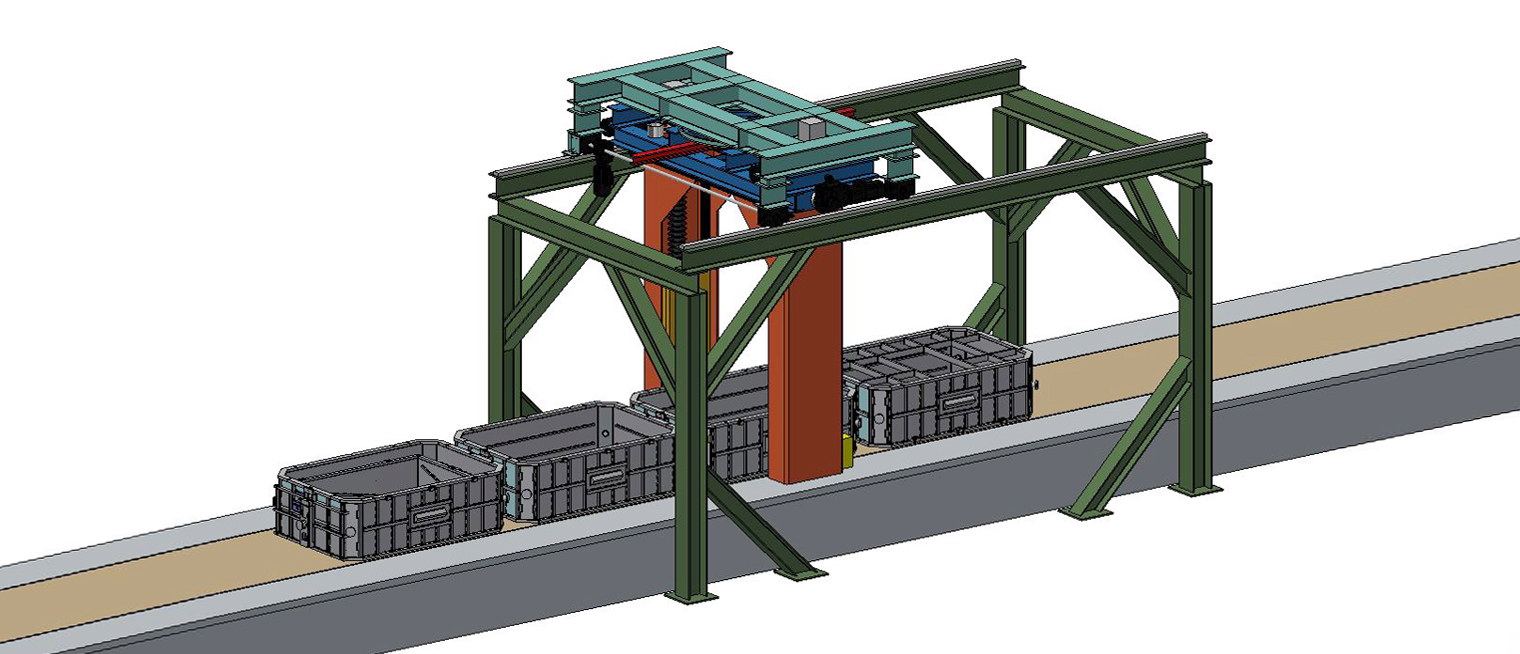

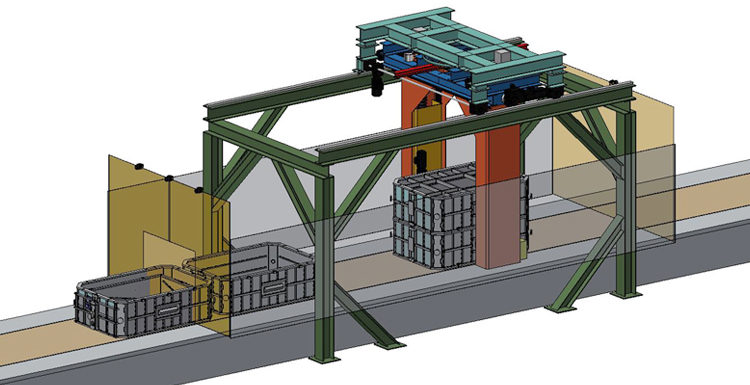

Example

Lifting-turning-setting device

for molds up to 8 tons

We bring your molds together.

The task

Handling

The customer needs a concept for joining molds. On an existing conveyor line, the upper mold must be turned and then placed on the lower mold.

The space conditions are very tight and the process must be carried out without personnel if possible.

The solution

The developed concept resulted in a handling module with the following functions/work steps:

- Various sensors are used to determine the position and orientation of the upper part of the casting mold.

- With the data, the drive axle moves to the correct position and turns the gripper parallel to the mold.

- Now both gripper jaws move independently inwards and stop on resistance of the mold.

- Two synchronized lifting spindles lift the mold and rotate it 180° with two synchronized swivel drives.

- The position and orientation of the lower part of the mold is determined by sensors.

- Using the data, the drive axis moves the upper part of the mold to the correct position and rotates it parallel to the lower part of the mold.

- The two synchronized lifting spindles reduce the height ofthe upper part of the casting mold until it rests on the lowerpart of the casting mold.

- When the lifting spindle is released, the stroke is stopped and the two gripper jaws move outwards.

- Safety is ensured with surface scanners.

Facts & figures

Capacity: 10 molds/hour

Alztec Team:

1 EE in design

Essentially planned components:

1 base frame

1 drive axle with rack and pinion drive

1 rotary axis with toothed ball slewing ring

2 gripper infeed with trapezoidal threaded spindle

2 lifting drive with trapezoidal threaded spindle

2 swivel axes with swivel drive

1 safety technology

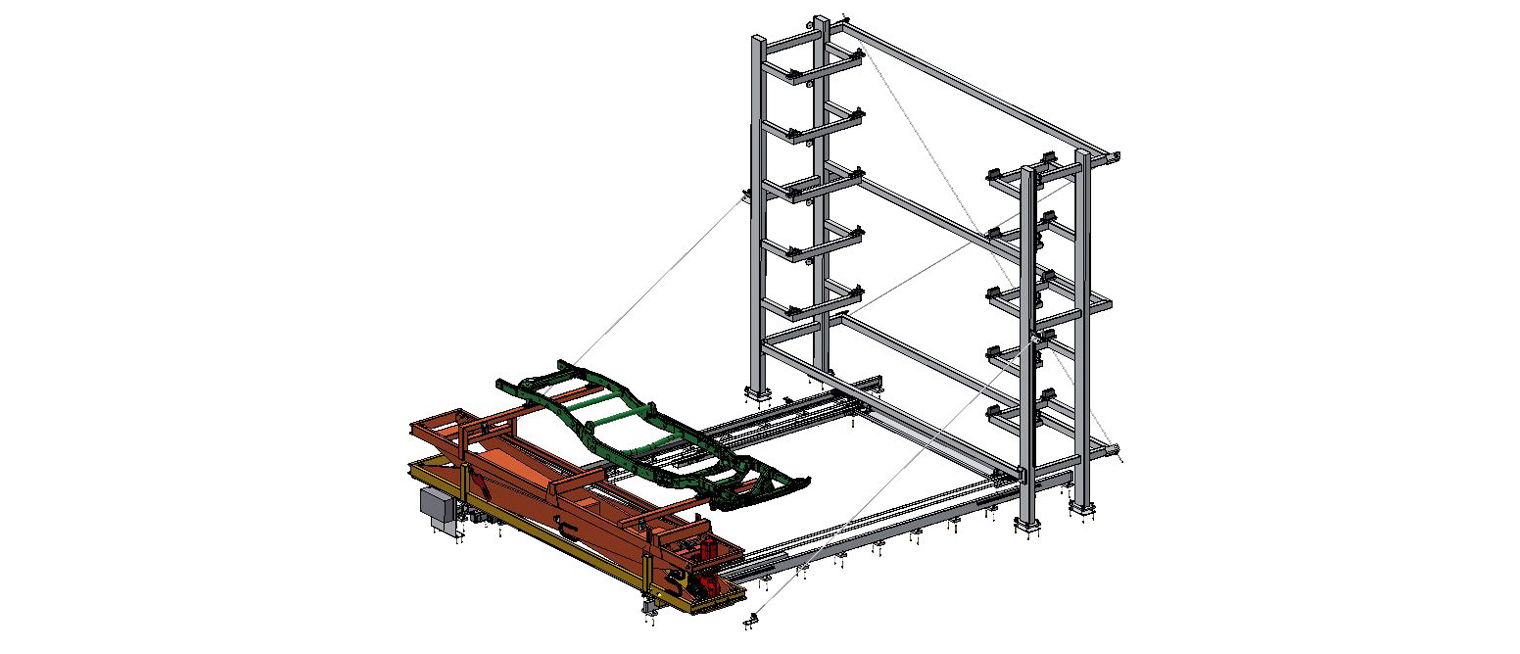

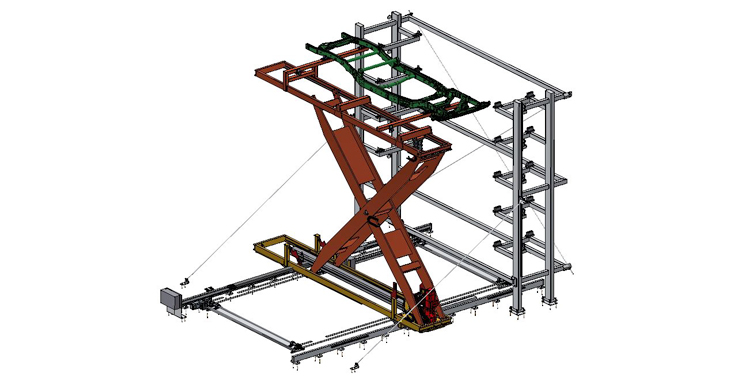

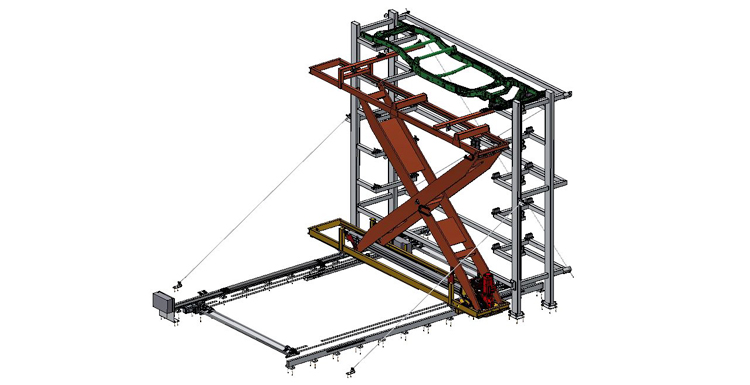

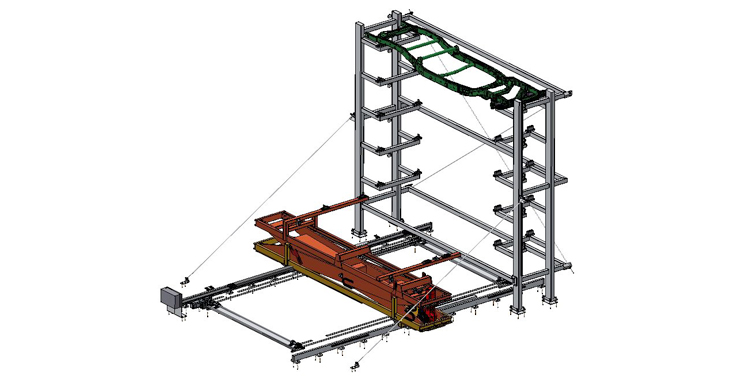

Example

Buffer system for ladder

frames of off-road vehicles

Almost weightlessly your products fly

into the warehouse.

The task

Handling

Storage

The customer requires a concept and design for two space-saving FIFO storage units for ladder frames of off-road vehicles. The storage should be able to buffer five frames. The takeover and handover is carried out to an on-site overhead conveyor system. The protection technology (protective fence and access protection) is in the scope of the customer.

The solution

The developed concept and its design resulted in a handling module with the following functions:

- Rail-mounted trolley with toothed belt drive for moving the ladder frames.

- Scissor lift system with a push chain for lifting and lowering the ladder frames. The supports on the lifting system are designed cantilevered so that the frames can be moved into a rack.

- By buffering the ladder frames in a rack, each frame can be accessed.

- The driving and lifting positions are determined by a laser distance measuring system.

- For safe and gentle transport and storage, the plastic holders were developed in close cooperation with the customer.

Facts & figures

Capacity: 12 ladder-fames/hour

Alztec Team:

1 EE in design

Essentially planned components:

1 drive axle with toothed belt drive

1 scissor lift with push chain

1 rack with 5 buffer places

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.