Conveying equipment

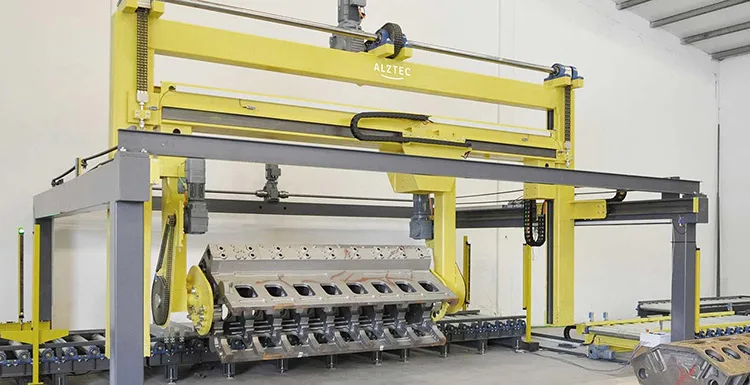

In perfect shape

for a foundry.

The task

Conveying

Storage

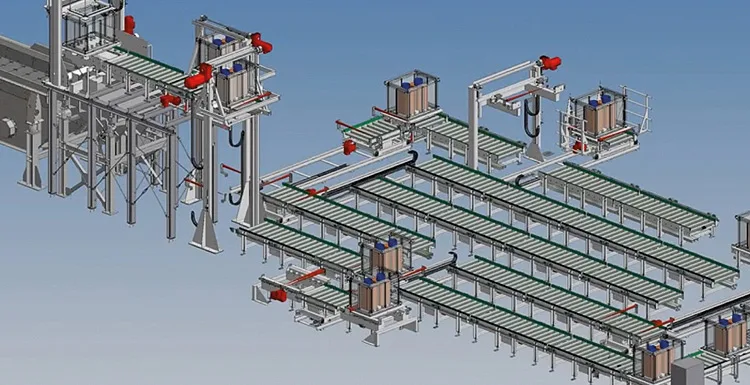

A foundry requires for the transport of the pallets with a “Jacket”, a conveying system which transports the pallets with the molds and the sand from the loading are via the casting station in a cooling station to the demolding station.

The solution

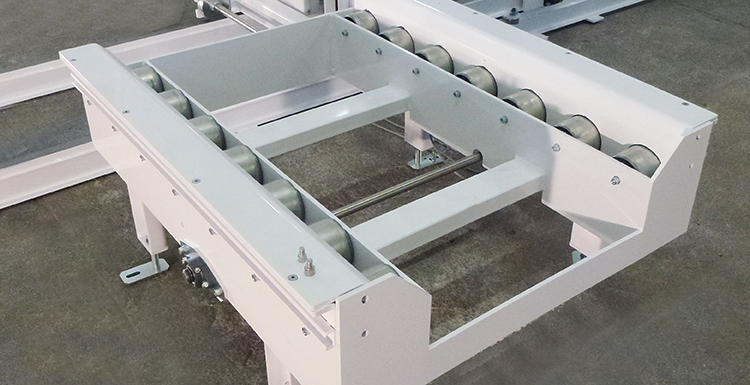

Massive roller conveyors essentially ensure the transport of the pallets with Jackets. The corner transfer units were fitted with chain conveyors on a Pneumatic lifting gear. The distribution of pallets with Jackets in the cooling off station, as well larger crossway distances were covered by distribution cars. Differences in height were overcome with Chain hoist lifters.

The core of the system is the Jacket Lifter with Pallet Tipper with the integrated cleaning function. In this station, by lifting the Jackets, the sand is drained into the vibration chute below. During lifting, brushes reach the inner sides of the Jackets and clean the latter from adhering sand. Once the Jackets are cleaned, the pallet is tilted by 90° so that the molds that are placed on it slide into the vibration chute. A rotating brush then cleans the sand residue from the pallet.

Facts & figures

Capacity: 360 pcs./day

Alztec Team:

4 EE in design

1 EE in assembly guide

Main components:

28 roller conveyors

5 distribution cars

4 corner conveyors 2 lifters

1 tilting device

1 jacket lifter

1 jacket lifter with brush

Videos

Video Conveyor technology 1

Video Conveyor technology 2

Video Conveyor technology foundry

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.