Handling with conveying

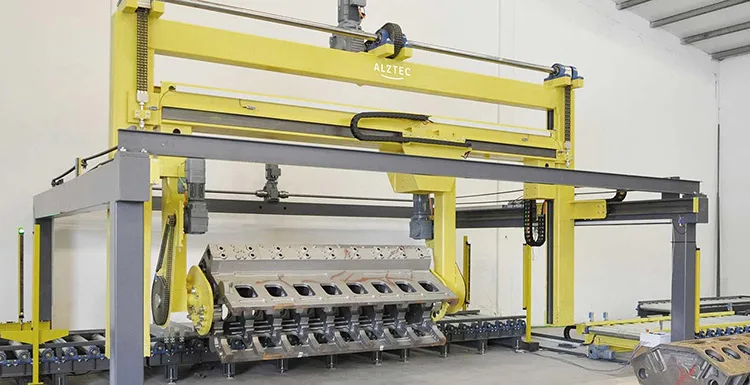

Submerged engine blocks.

The task

Handling

Conveying

Various types of engine blocks with a weight of up to 5,000 kg shall be painted after a warm-up phase by a dipping bath in the furnace.

The solution

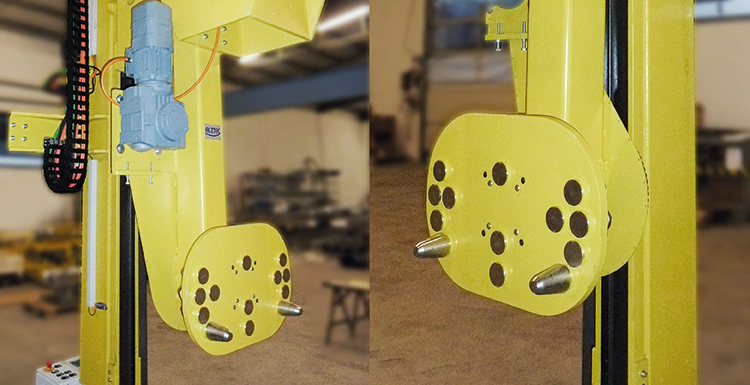

The engine blocks are transported using conventional roller conveyors and a distribution car. The handling developed specially for this application is the central element of the plant. While the engine block is transported by the roller conveyor to the grappler on the left-hand side, the right-hand grappler moves towards the engine block and locks it between the holders. The handling system lifts the engine and moves it over the painting basin. After the rotating function has been started, the engine block is moved into the painting basin. After a preset time, the handling system retracts and the engine block remains above the painting basin for a predetermined time to drain off. Subsequently the engine block will be transferred again to the conveyor system, which transports it out for approval.

Facts & figures

Capacity: 5.000 kg

Alztec Team:

2 EE in design

4 EE in assembly and commissioning

1 EE in electrics and control engineering

Main components:

1 handling module

60 m conveying track

1 plant control incl. visualisation

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.