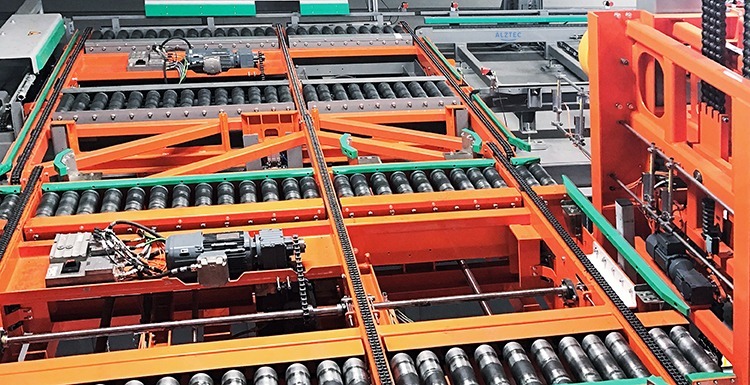

Commissioning in a big way!

The task

Conveying

Storage

Handling

Plastic parts are painted in an automotive plant. The end customer’s requirement is to provide the more than 600 possible different parts (in unmixed containers) in a specific order in picking containers and to store as many containers as possible (unmixed, empty and full picking containers).

The solution

The unmixed container arriving at the goods receiving area is measured fully automatically and placed on a load carrier with a staple-module. Given the large number of containers, it was challenging to securely grip all of them and turn them so that the opening would later face the worker. The load carrier incl. product is transported to the corresponding storage area on the 1st floor. On the ground floor, picking is carried out by the customer’s employees. At 6 stations, the station lifter provides the corresponding unmixed containers according to a predefined sequence. The employees remove parts from the containers provided one after the other and fill a picking container. Each of the 6 stations has its own range of parts and geometrically different picking containers. The finished picking containers are transported by a double distribution truck and returned to the warehouse via a lifter and stacker crane. There, the picking containers are waiting to be called off to the assembly line, fed to it, emptied and returned. In order to cover the high cycle time, a total of 8 stacker cranes are used on 3 rails, each 150 m long.

Facts & figures

Capacity: 250 pcs./day

Alztec team:

10 EE in design

20 EE in assembly / commissioning

8 EE in electrics / control engineering

Main components:

3 aisles with

8 stacker cranes with telescope

1 shelf

9 lifters

1 double-distribution trolley

5 distribution trolleys

2 staple-modules (rotating)

2 staple-modules

230 metres conveyors

900 load carrier

48 commissioning gates

1 system control including visualization

1 warehouse management system

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.