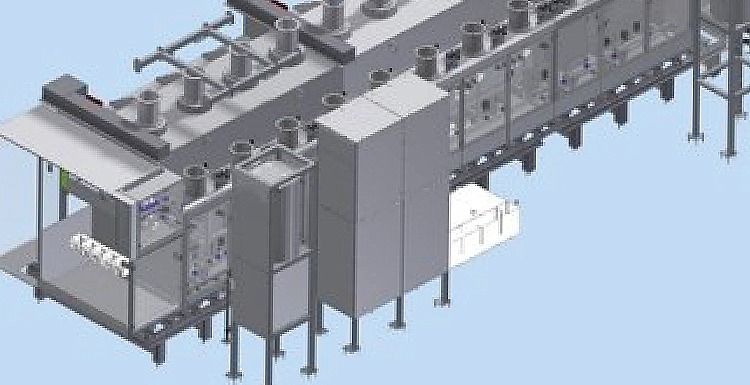

Processing plant

Parts per trillion –

highest purity –

unique Alztec

process.

The task

Conveying

Processing

The world’s largest producer of polysilicon wants to automate the breaking, sorting, cleaning and packaging of polysilicon and increase the purity of its product. The facility is intended to process 4,000 t of high-purity polysilicon for further use in the electronics industry. The customer material is brought to the system in logs of approx. 70 kg each. In the end, the broken and cleaned polysilicon should come out of the plant fully automatically in bags of 5 kg (±50 g). Additional requirements are the high purity < 500ppt and the exact material tracking according to SEMI criteria.

The solution

Alztec designed and supplied this revolutionary system including the material management system. The high level of purity was achieved using special materials and patented processes.

The crushing of the polysilicon is realized by non- contact high-voltage pulse breaking with 200 KV and 5 Hz, which already ensures a high purity of the polysilicon at this stage. In a next step, the crushed material subdivided by a special wet screen equipment into various fractions is filled into several etching baskets. Some µm of the surface are eroded by wet chemical processes through a connected etching plant, ensuring thereby a maximum cleanliness. Finally, the ultra-clean material will be dried and packed into PE double bags.

Facts & figures

Capacity: 4.000 tons/day

Alztec team:

8 EE in design

10 EE in assembly / commissioning

6 EE in electrics / control engineering

Main components:

1 high voltage impulse breakage

1 screening equipment

150 metres basket conveying

300 etching baskets

1 etching plant

1 drying plant

3 bag packaging plant

1 plant control including visualization

1 warehousemanagementsystem

Videos

Video Cleanroom equipment

Video Crushing – Screening – Etching

Video Polysilicon handling

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.