Packaging plant

Highly compact packaging

under pressure.

The task

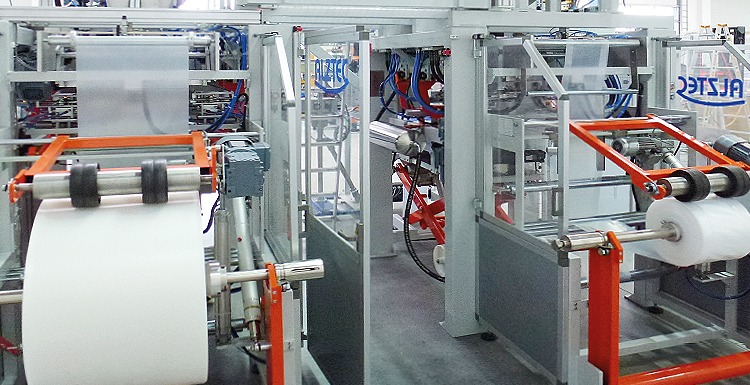

Conveying

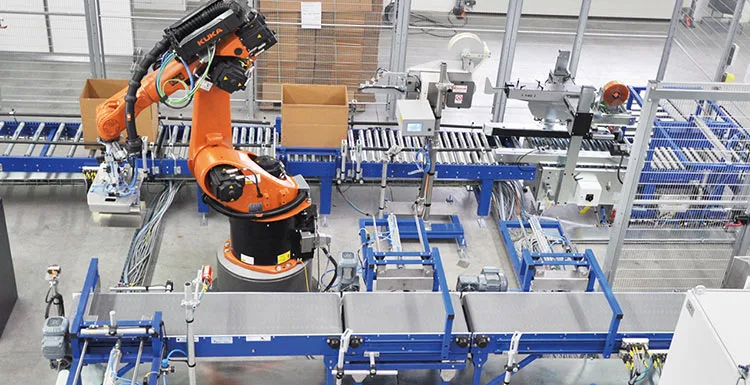

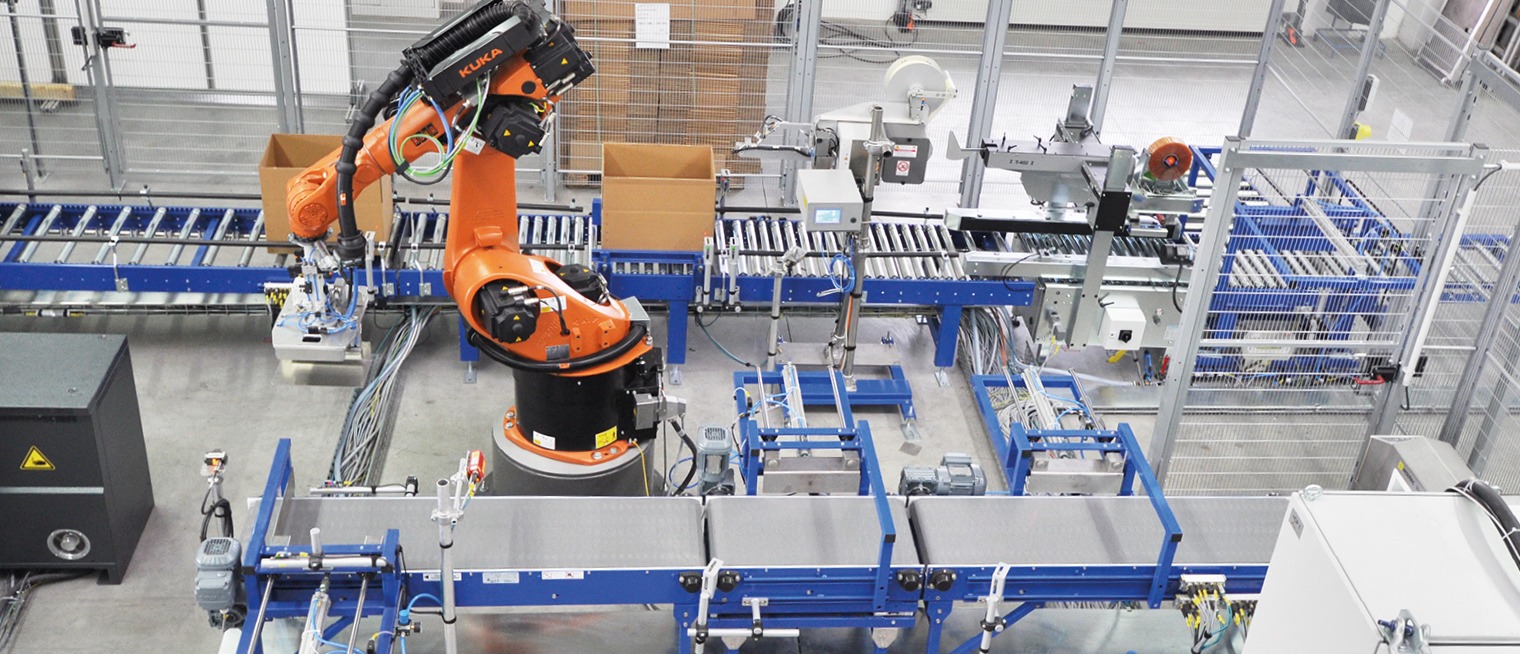

Handling

A Chinese-American joint venture company was looking for a special solution for compact, automated packaging of granular silicon. The silicon granules are delivered through a pipeline with a special coating and should be packed in bags of 10kg (±10g) with a vacuum of 200 mbar. At the end of the system, fully automatically packed cartons are to be output on weatherproof packed pallets. A throughput of at least 200 bags per hour is required.

The solution

The silicon granules produced in a new process can now be packed fully automatically using the special Alztec system. The Alztec team achieves the task with two VFFS (VERTICAL FORM FILL and SEAL) packaging systems, in which the bag is first made from foil material, then filled, evacuated and finally sealed.

The material is double-bagged, both bags are labeled and, after checking the weight and metal, they are packed into cartons by a robot. The carton is then stacked on a pallet by another robot. The filled pallet is weatherproof packed and can be removed with the forklift at the end of the system.

A special challenge was the coating of parts that come into contact with the product with silicon nitride and the high negative pressure in the bag, which could be solved by the Alztec know- how.

Facts & figures

Capacity: 5.000 tons/year

Alztec team:

5 EE in design

8 EE in assembly / commissioning

6 EE in electrics / control engineering

Main components:

1 packaging plant inner bag

1 packaging plant outer bag

80 metres bag conveying means

1 clean room lock

1 metal detector

1 robot cell for bag packaging

1 box lifter / closing

30 metres box conveying engineering

1 robot cell for palletizing

5 labeling

25 metres pallet conveying engineering

1 stretch binder

1 plant control including visualization

1 material management system

Which task do you wish to come

true for your organization?

Let’s talk about your needs & requirements.

Just call or send us a mail.